PA-S Q

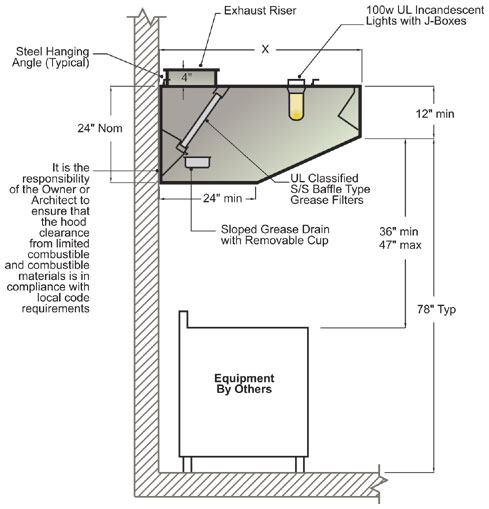

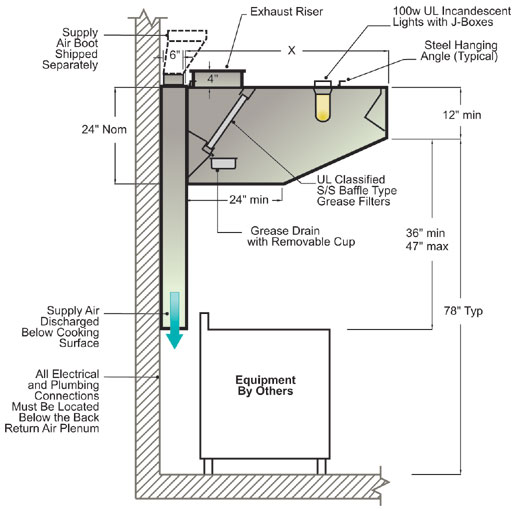

Exhaust Only Hood with Optional Rear Supply Plenum

Features at a Glance

- Superior exhaust flow rates (A 4' Hood can operate at 228 CFM/ft or 912 total CFM.)

- ETL Listed for use over 400°F and 600°F cooking surface temperatures, provides flexibility in designing kitchen ventilation systems. ETL Listed to Canadian safety standards, ETL Sanitation Listed and built in accordance with NFPA 96.

- ETL Listed to Canadian safety standards, ETL Sanitation Listed and built in accordance with NFPA 96.

- Sloped front for low ceiling applications.

- Front design prevents condensation and directs grease-laden vapors toward the exhaust filter bank.

- Polished stainless steel on the interior and exterior of the front enhance aesthetics.

- Up to 90% make-up air can be supplied through optional rear plenum on the PA-S-DP Q model.

- Sturdy stainless steel construction with double wall, insulated front panel.

- Factory pre-wired lighting to illuminate the cooking surface.

- Aluminum filters with optional stainless steel, Captrate®, or high velocity cartridge filters (Model PA-S-C Q).

- Optional integral clearance to combustibles reduction system to meet NFPA 96 requirements.

- Optional UL Listed light and fan control switches flush mounted and pre-wired through electrical chaseway.

- Exceptional capture and containment of cooking vapors. This is accomplished with the "triangle" on the front of the hood's capture area and the "C-shaped" design of the hood's capture area.

Options

- Utility Cabinet - ETL Listed for integral side mount on the K-Tech ventilation hood, fabricated of same material as hood. The cabinet can house a factory pre-piped UL Listed fire suppression system* and ETL Listed, pre-wired electrical controls with light switches, lighted fan control switches and internal factory wiring and components (starters, relays, etc.) to reduce field wiring requirements, or the ETL Listed Energy Management System with ETL electrical controls. ETL tests confirm temperatures do not exceed 120°F inside the cabinet during fire condition. (120°F is the maximum allowed storage temperature for the UL Listed fire suppression system and the ETL Listed Industrial control panel. (*Dimensional restrictions may apply)

- Rear Make-Up Air Plenum - Provides make-up air for the kitchen, discharged below cooking equipment. Welded. Stainless steel exposed surfaces. Unexposed surfaces made of aluminized metal. Shipped separately, requiring field connection. Insulated to prevent condensation. Perforated diffuser plates for even air distribution. Provides required clearance from limited combustibles per NFPA 96 Standards.

- Front Perforated Supply Plenum - Provides low velocity make-up air for the kitchen, discharged in front of the hood. Welded. Stainless steel. Perforated diffuser plates for even air distribution. Supply riser includes a volume damper for easy balancing.

- Removable ETL Listed High-Velocity Cartridge Filter - Constructed of stainless steel. Uses centrifugal force to remove grease and other particulates. National Institute of Standards and Technology methodology used by an independent agency to evaluate performance, tests indicate 95 percent extraction efficiency.

- Captrate® Filter - Removable Combo Filter witch combines stainless steel baffle with a unique high tech patented ceramic filter. Provides highest level of grease removal. Meets UL 1046 and NFPA No. 96 requirements.

- Enclosure Panels - Constructed of stainless steel. Mounting channel factory-welded to hood for field installation of panels over 11" high. Under 11", factory-welded and integrally installed into hood front ends. Sized to extend from hood top to ceiling, enclosing pipe and hanging parts.

- End Panels - Should be used to maximize hood performance and eliminate the effects of cross drafts in kitchen. Units constructed of stainless steel and sized according to hood width and cooking equipment. Exposed edges hemmed for safety and rigidity.

- Heated Make-Up Air - ETL Listed direct fired gas heated make-up air unit. ETL Listed for natural gas and propane. Design integrates the blower and burner into a single package. Heavy duty, weather resistant, galvanized steel construction. Units available in Roof Top Package or as a stand alone heated make-up air module. Several sizes available to meet almost any performance rating specification.

Performance Data

| Model | Configuration | Avg. Cooking Surface Temp. (°F) | Min Exhaust CFM/ft. | Supply CFM/ft. via Rear MUA Plenum |

| PA-S Q, PA-S-DP Q |

Single Wall Hood | 400°F - Ovens, Steamers, Kettles, Open-Burner Ranges, Griddles, Fryers | 228 | 205 (80%) |

| PA-S Q, PA-S-DP Q |

2 Wall Hoods Back-to-Back in an Island Configuration | 400°F - Ovens, Steamers, Kettles, Open-Burner Ranges, Griddles, Fryers | 456 | 410 (80%) |

| PA-S Q, PA-S-DP Q |

Single Wall Hood | 600°F - Gas Charbroilers, Electric Charbroilers | 294 | 235 (80%) |

| PA-S Q, PA-S-DP Q |

2 Wall Hoods Back-to-Back in an Island Configuration | 600°F - Gas Charbroilers, Electric Charbroilers | 588 | 470 (80%) |

Construction

- Available in single wall type or two piece back-to-back island configuration.

- Fabricated of Type 430 stainless steel, #3 or #4 polish, on all exposed surfaces. Optional type 304 stainless steel available.

- Double-wall, insulated front increases rigidity and reduces condensation.

- Fitted with UL Classified, baffle-type stainless steel filters, removable for cleaning. Optional ETL Listed high velocity cartridge filters available on the CSND model.

- Grease drain system (1/8" per foot minimum slope) with removable pint cup for easy cleaning.

- Pre-punched hanging angles on each end of hood. Additional set provided for hoods longer than 12'.

- Optional integral clearance to combustibles reduction system to meet NFPA 96 requirements.

- Fitted with UL Listed, pre-wired, incandescent light fixtures and plastic-coated glass globes to hold up to a standard 100 watt bulb. Recessed incandescent and recessed fluorescent lights optional.

- A built-in wiring chase provided for optimal positioning of electrical controls and outlets on the front face of the hood without penetrating capture area or requiring external chaseway.

- The PA-S Q model is ETL Listed for 400°F, 600°F and 700°F cooking surfaces (File 3054804-001 without exhaust damper), ETL Sanitation Listed and built in accordance with NFPA Standard 96.

Sectional View

PA-S-DP-Q

Certifications

The PA-S Q Model has been certified by ITS. This certification mark indicates that the product has been tested to and has met the minimum requirements of a widely recognized (consensus) U.S. and Canadian products safety standard, that the manufacturing site has been audited, and that the applicant has agreed to a program of periodic factory follow-up inspections to verify continued performance.

Models PA-S Q are ETL Listed under file number 3054804-001 and complies with UL710 Standards and ULC710 Standards.